Floor leveling involves using specific construction techniques to achieve a desired level of smoothness on the original surface, meeting the requirements of various uses. Traditional floor leveling methods usually rely on manually applying cement plaster mortar, mainly for basic leveling needs. However, as there is a growing emphasis on indoor comfort and habitability, the functional demands for floors have become more intricate, leading to higher expectations for the material performance used in floor leveling.

In the realm of traditional floor leveling materials, performance is primarily delineated through the prism of compressive strength indicators. Yet, these conventional materials fall short in their capability to exhibit substantial self-leveling fluidity, efficacious sound insulation properties, robust thermal stability, and exceptional adhesive prowess. This deficiency invariably gives rise to post-construction issues encompassing hollowness, fissuring, and detachment within the leveled floor. In more severe instances, these complications may even culminate in the propagation of inter-floor noises and widescale impairment of the floor finish. Furthermore, with escalating labor costs, the conventional floor leveling methodology proves inadequate in meeting the imperative of curtailing construction expenses. It is in light of these considerations that the pursuit of rapid, high-efficiency floor leveling techniques assumes pivotal significance within the contemporary construction landscape.

VASA Tech Holdings Group's Floor Leveling System is an integrated solution designed to address diverse floor leveling challenges, customized to meet distinct functional requirements. This comprehensive system focuses on optimizing and enhancing floor leveling construction processes, thus reducing construction timelines and overall costs. For instance, when it comes to traditional wooden flooring or PVC material installations requiring floor leveling, our self-leveling mortar system offers a short construction period, high bonding strength, low shrinkage, and excellent self-leveling properties. Furthermore, our underfloor heating floor leveling system provides remarkable sound insulation, rapid high-strength development, exceptional self-leveling capabilities, and unparalleled thermal stability, thus creating an environment of comfort and tranquility.

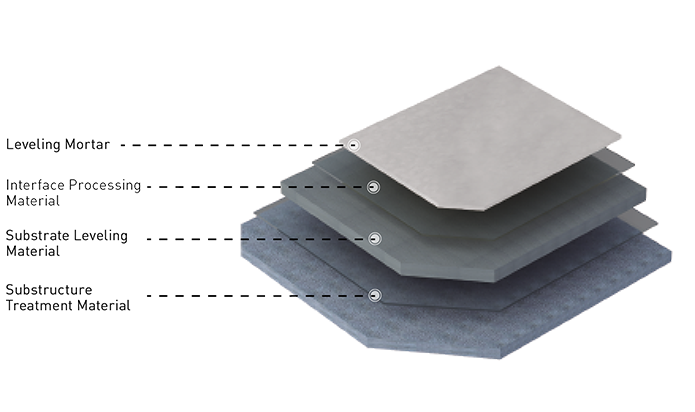

Layers: substructure treatment material, substrate leveling material, interface processing material, leveling mortar

| Layers | Product Type | Features |

|---|---|---|

Substructure Treatment Material | Interface Treatment Agent (Primer) | Excellent permeability and sealing, convenient construction. |

Substrate Leveling Material | Dry-mixed Plastering Mortar | Convenient construction, high strength, crack resistance. |

Interface Processing Material | Liquid Interface Treatment Agent | Good permeability and sealing, convenient construction. |

Leveling Mortar | Surface Cementitious Self-leveling Mortar | Smooth and even surface, high strength rapid hardening, surface wear resistance, low shrinkage. |

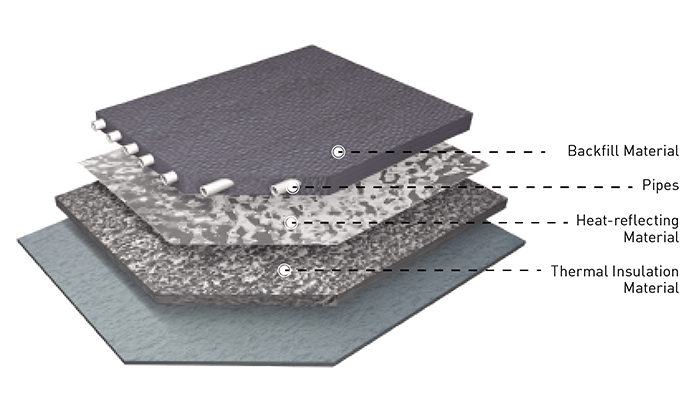

Layers: thermal insulation material, heat-reflecting material, pipes, backfill material

| Layers | Product Type | Features |

|---|---|---|

Thermal Insulation Material | Insulation Board, Insulation Slurry, etc. | Heat preservation and heat insulation function. |

Heat-reflecting Material | Hydronic Piping System, Aluminum Foil, etc. | ———— |

Backfill Materials | Leveling Mortar | Smooth and flat, high strength fast curing, surface wear resistance, low shrinkage. |

Gypsum Self-leveling Compound | Excellent flowability, superior leveling effect, rapid early strength development, low shrinkage, crack-free and void-free, safe and environmentally friendly. |